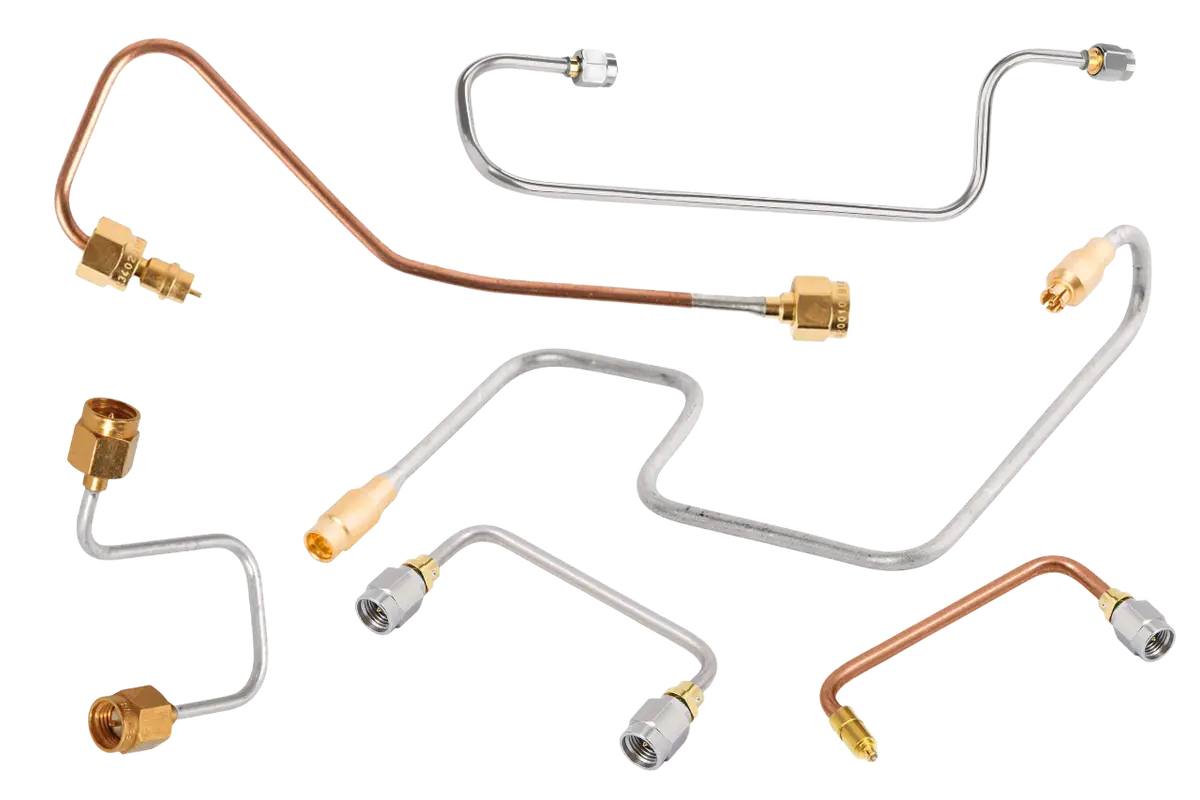

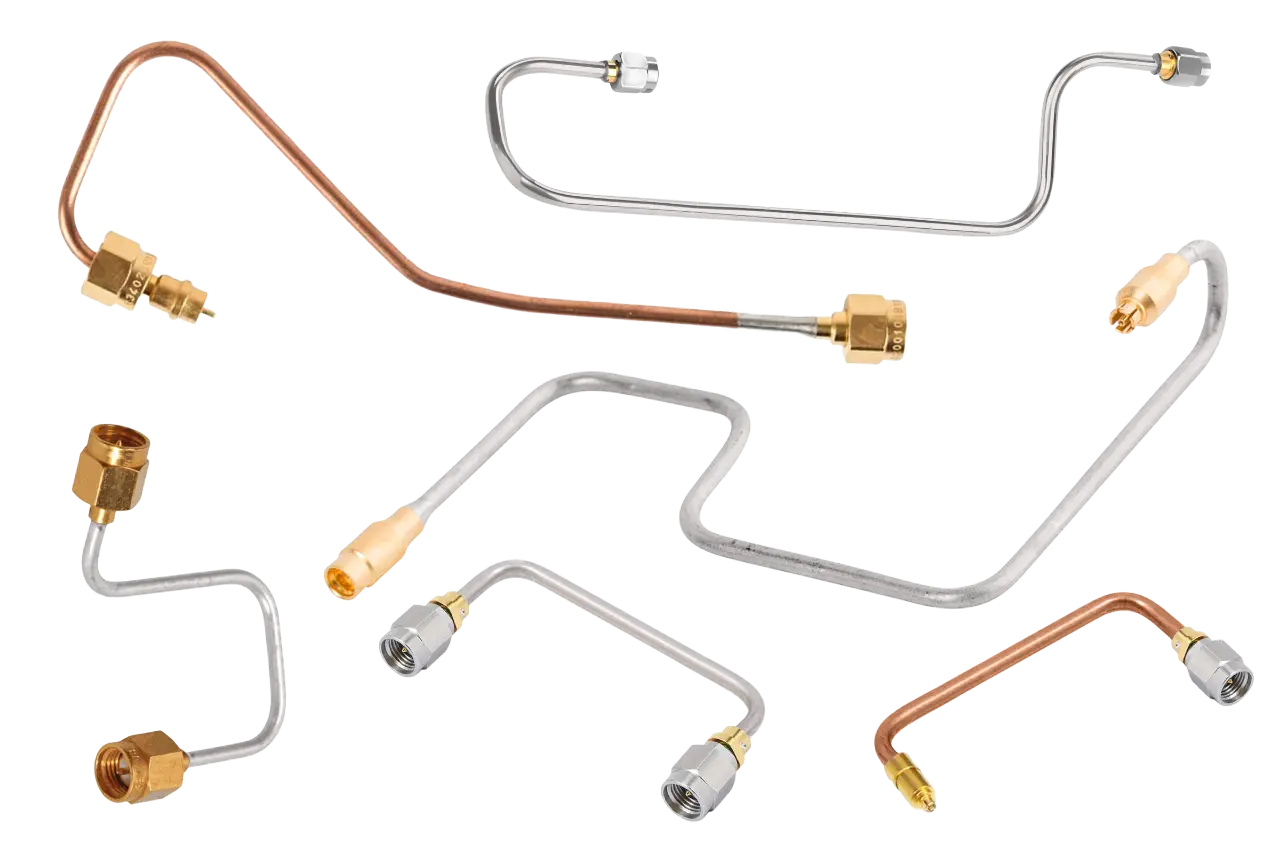

Semi-Rigid RF Cable Assemblies

Install Them and Forget About Them

The king of rock solid RF performance.

Overview

Airborne radar and avionics modules

Airborne radar and avionics modules Satellite payload and ground links

Satellite payload and ground links Microwave instrumentation and test fixtures

Microwave instrumentation and test fixtures Defense communication and signal routing modules

Defense communication and signal routing modules High-density RF enclosures requiring bend-to-fit precision

High-density RF enclosures requiring bend-to-fit precision

ConductRF’s Semi-rigid RF Cable Assemblies offer the highest level of electrical performance and EMI shielding available in an RF coaxial interconnect. These mechanically formed solutions are engineered for applications where low loss (signal attenuation) and phase stability are non-negotiable. They’re built with solid copper or copper-clad stainless steel outer conductors that are machine shaped to your exact physical spacing requirement. The result is the most stable interconnect you can achieve. Ideal for microwave modules, test systems, aerospace instrumentation, and military systems, semi-rigid assemblies provide unmatched signal integrity with zero flex movement.

What Makes a ConductRF Semi-Rigid RF Cable Assembly “Semi-Rigid”?

Unlike flexible or formable alternatives, semi-rigid assemblies use a hard outer conductor that must be pre-bent into its final shape before installation. This structure locks the cable geometry in place, eliminating the performance drift seen in re-bendable or flexible designs. ConductRF offers a range of semi-rigid diameters and termination options, allowing you to define the exact routing and RF performance your system demands.

Up to 110 GHz with 1.0 mm Nano connectors

As low as 0.03–0.15 dB/ft @ 10 GHz

±1° over temperature

20–30 dB

As low as 1.05:1 (translates to very high return loss)

As high as 130 dB (phase-stable variants can reach >165 dB)

0.047", 0.086", 0.141", 0.250"

~3× cable OD

- O.047”: as tight as 0.XX”

- 0.086": as tight as 0.25"

- 0.141": as tight as 0.25”

- 0.250": as tight as 0.50”

~500–800 lb/in²

Very high

- Solid copper or silver plated copper (for lowest loss/highest power semi-rigid RF cable assemblies)

- Stranded copper

- Copper clad steel (most common for semi-rigid RF cable assemblies)

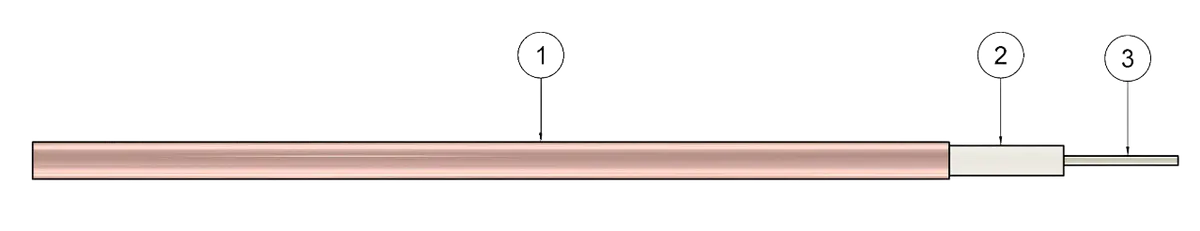

Anatomy of a Semi-Rigid rf cable

- 1

Center Conductor

Copper

Options & Customization

Jacketing Options

Jacketing Material | Properties | Ideal Use Case |

|---|---|---|

Tin Plated Copper | Low loss, flexible, easily formed | High-frequency, lab setups, custom bends |

Stainless Steel | Rugged, crush- & corrosion-resistant | Military, aerospace, industrial, marine |

Strain Relief, Boots, and Marking Options

Option Type | Description | Benefits | Typical Use |

|---|---|---|---|

Overmolded Boots | Molded plastic or rubber boots around connector | Improved strain relief, sealed ingress protection | Ruggedized field use, outdoor |

Color Coded Sleeves | Color plastic or silicone identifiers | Fast visual cable ID | Test labs, telecom panels |

Heat Shrink ID Labels | Printable or custom ID wraps | Durable labeling | Aerospace, medical, precision systems |

Laser or Inkjet Marking | Permanent direct-to-cable marking | Clean and compliant | Defense, industrial environments |

Connector Mating Types

Mating Interface | Frequency Range | Application Notes |

|---|---|---|

SMA | DC 18 GHz | General use, telecom, military |

N Type | DC 11 GHz | Rugged field applications |

TNC | DC 11 GHz | Similar to SMA but with threaded security |

SMP/SMPM | DC–40 / 65 GHz | Miniature, high-frequency board-to-board |

2.92mm (K) | DC–40 GHz | Precision testing |

2.4mm | DC 50 GHz | Ultra-high-frequency lab testing |

1.85mm (V) | DC 67 GHz | Aerospace and test setups |

Cable to Connector Termination Styles

Termination Style | Description | Ideal Use Case |

|---|---|---|

Crimp | Connector ferrule compressed around braid | Field serviceable, fast assembly, used with all common cable sizes |

Solder | Core and/or braid soldered into place | Higher performance, permanent |

Clamp | Mechanical clamp secures braid | Reusable, lower cost |

Compression | Tool-less press-fit connection | Quick install, serviceable |

Field replaceable | Modular connector ends | Maintenance or rework systems |

Overmolded | Fully sealed with molded boot | Rugged, waterproof, outdoor use |