Why Conduct RF?

Because when your RF signal matters, your cable assembly choices matter even more.

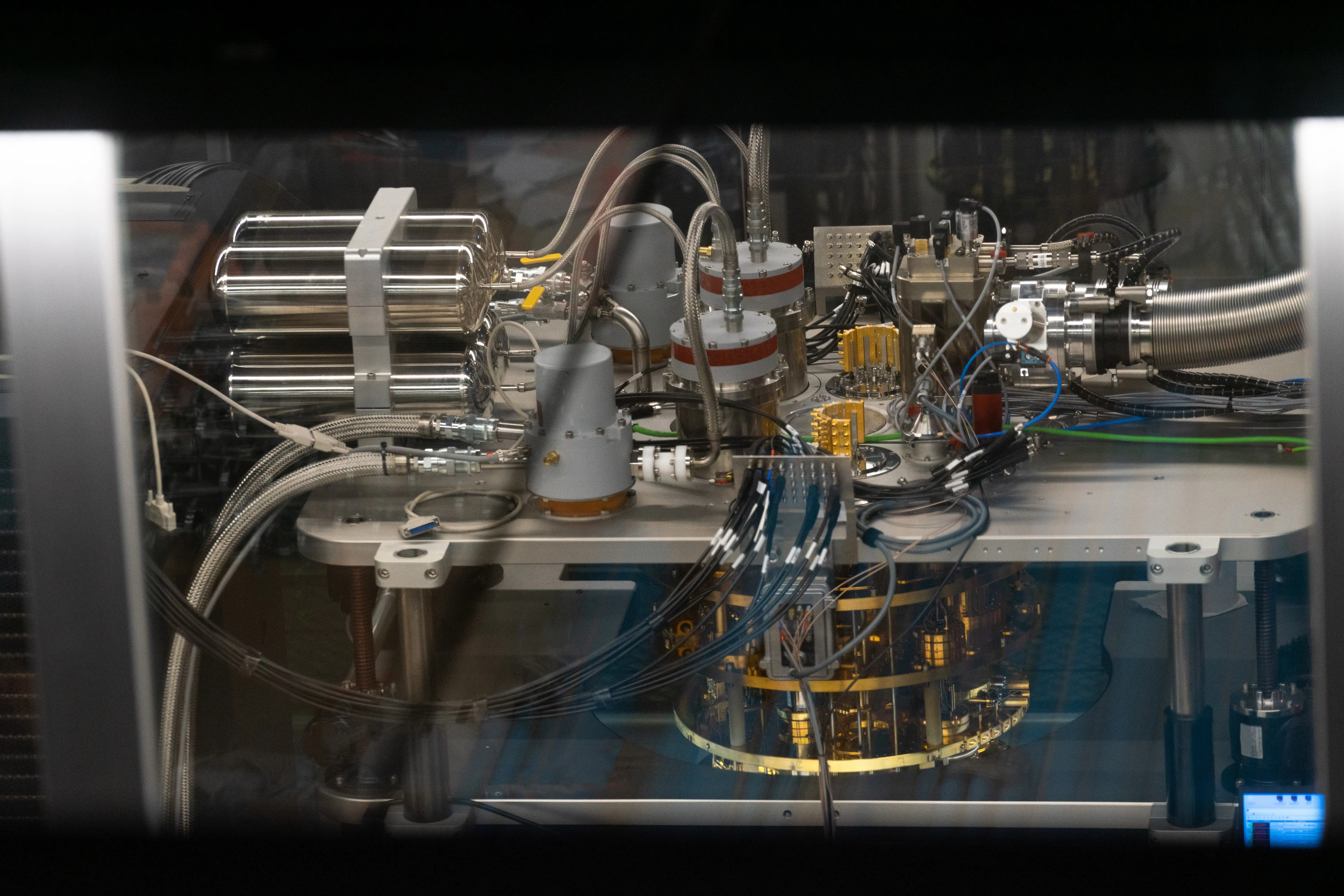

Among the transmit and receive electronics in RF systems is the most critical design decision hiding in plain sight—the RF Cable Assembly. Improperly designed, manufactured, and implemented they’re a sure, and potentially lethal, failure point. But properly optimized from end-to-end they become a game-changing component of system precision and dependability.

That’s why, in addition to offering expert assembly and testing services, ConductRF offers a broad and evolving range of coaxial cable types, connector options, and jacketing configurations to ensure engineers and sourcing professionals receive exactly what their application demands.

Whether you need ultra-flexible cables for dense routing, low-loss performance at high frequencies, ruggedized reliability for harsh environments, or EMI containment for mission-critical communications—we’ve curated a supply of proven cable and connector components and enhancement options to meet nearly every requirement for fast delivery of the best RF Cable Assemblies for your RF, microwave, and millimeterwave applications.

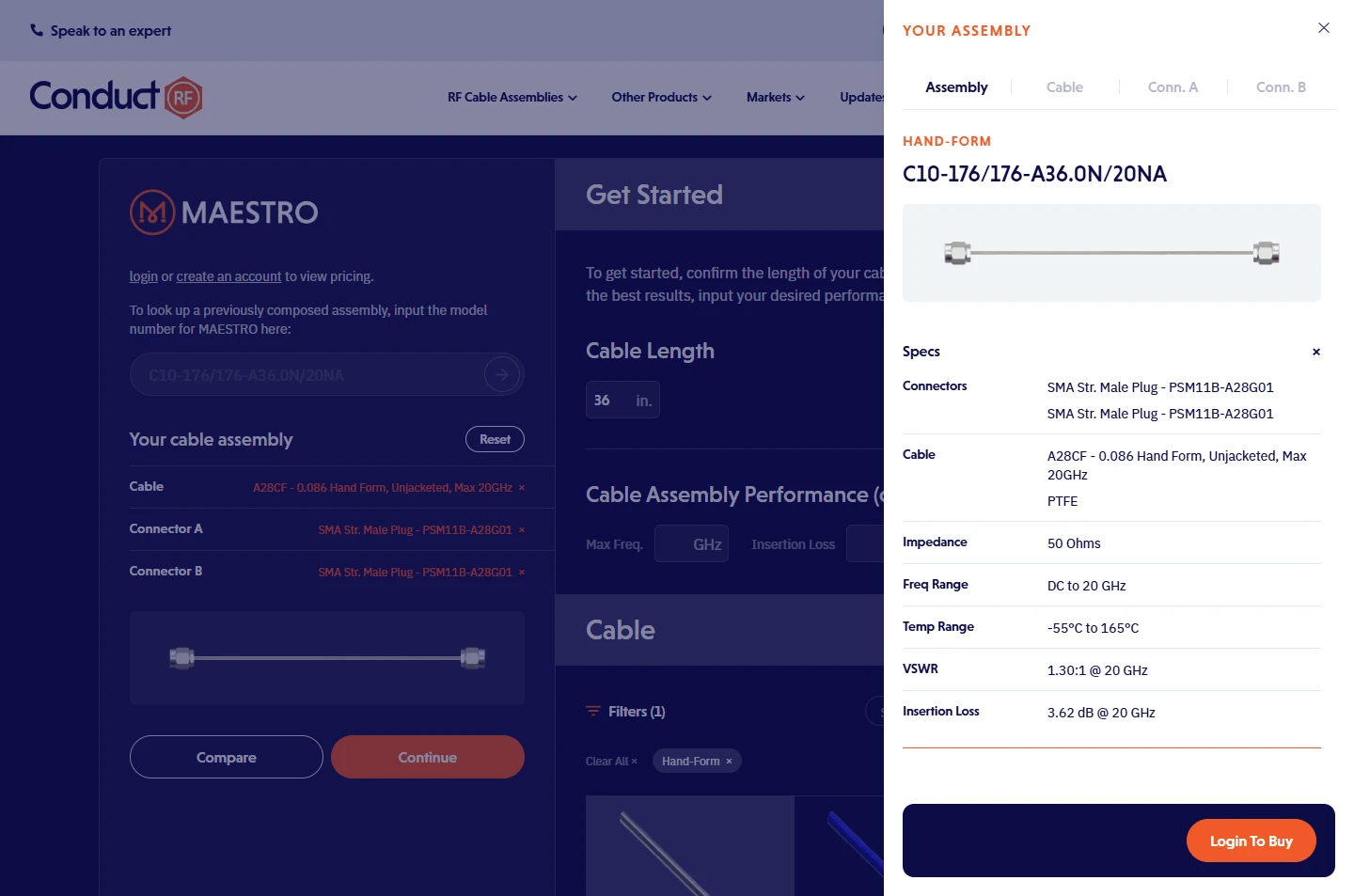

Compose the Perfect RF Cable Assembly with MAESTRO

With just a few clicks and a bit of information, MAESTRO will bring the ideal cable and connector combination right up for you.

Compose with MAESTRONote: To view pricing, and to place orders, you will need to establish a preferred customer account.

Enter Length and Desired Specs

Provide MAESTRO with the length of the cable assembly you’re composing and performance specs, if any.

Select Your Cable Style and Connectors

Use different filters to narrow your search. This choice, plus step 1, automatically impacts your choice of connector options.

Compare, Add to Cart, and Place Order

MAESTRO will present a table with your assembly up top and offer options for you to compare against that might also be suitable.

A Dedicated, Fully Equipped and Expertly Staffed USA Facility

Every ConductRF cable assembly—whether Flexible, Hand-Formable, Semi-Flexible, Semi-Rigid, Ruggedized, or Multi-Signal—is manufactured in our advanced U.S. facility. We’ve invested in the specialized tools that precision RF and microwave assemblies demand, including laser stripping systems for exact cable prep without damaging delicate dielectrics, CNC bending and forming equipment for consistent geometry, precision soldering and crimping stations, and environmental conditioning systems for ruggedization processes.

Our in-house testing lab is equipped for full high-frequency electrical validation, including vector network analysis up to 70 GHz, time-domain reflectometry, and phase stability verification. Each workstation is run by experienced technicians and supported by application engineers who understand the critical link between electrical performance, mechanical durability, and environmental resilience—ensuring every assembly we ship meets both your specifications and our own exacting standards.

Quick Turn Manufacturing and Delivery

ConductRF supports fast, reliable lead times. Our typical production window is just 5–10 business days from order to shipment for most standard and semi-custom configurations. Rapid prototyping and quick-turn manufacturing are core to our value. Need it faster? Contact our team to request expedited options or split delivery.

Customer and Design Support from a Dedicated Team

We don’t just manufacture cable—we help solve problems. With over 25 years of experience in application engineering and RF interconnect design, our team is ready to work with you to optimize performance, streamline routing, meet compliance requirements, or evaluate build-to-print designs for manufacturability and cost control.

Every Lot. Every Time. 100% Tested.

Quality assurance is at the core of our manufacturing process. Every lot of cable assemblies is 100% tested for electrical performance—ensuring insertion loss, return loss, and continuity meet or exceed your spec before anything leaves our floor. No exceptions. Just performance you can rely on.

Accreditations

We’re Registered and Certified to Deliver to Your Highest Standards for Compliance

For engineers and procurement professionals sourcing RF and microwave interconnects, we understand the high-stakes, highly regulated landscape you operate in—and we are fully equipped to help you stay compliant.

ConductRF assemblies are designed and built to meet a variety of military, aerospace, and commercial standards, including:

- ISO 9001 (PDF) (AS9100-pending)

- ITAR (PDF)

- RoHS (PDF)

- REACH (PDF)

- UL CL3P, UL CMP

- LSZH: IEC 60332, IEC 61034

- MIL-STD-202

- IL-STD-810

- MIL-DTL-17

- MIL-DTL-24643

ConductRF is currently ISO 9001:2015 registered and actively pursuing AS9100 certification, with full registration expected by the first quarter of 2026. ISO 9001:2015 sets the foundation for consistent quality across all our manufacturing and business processes, while AS9100 will add rigorous requirements for the aerospace and defense sectors, including lot traceability, documentation, and risk management.

In addition, ConductRF is an ITAR-registered (US export approved) military contractor and manufacturer. We are also fully compliant with both RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). These certifications matter because they ensure your assemblies meet stringent environmental, safety, and export requirements.

Our markets

Trusted by the World's Toughest Customers

Our products

Learn more about our RF Cable Assembly Types

ConductRF Also Builds With These Proven Suppliers